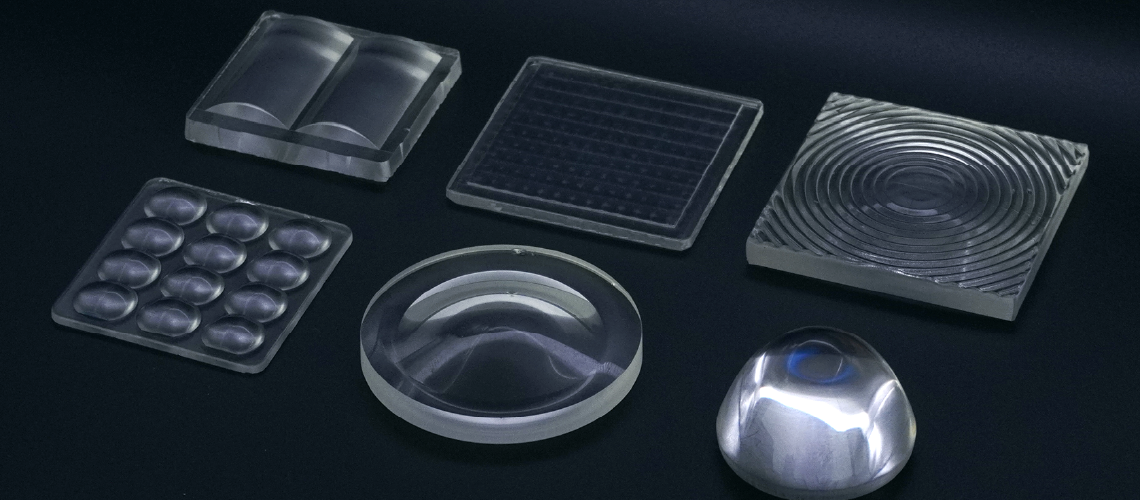

Lens processing by commissioning

Lens processing utilizing manufacturing technology for glass forming machine

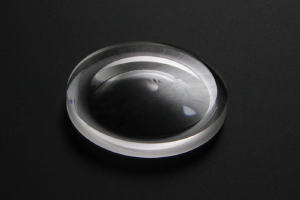

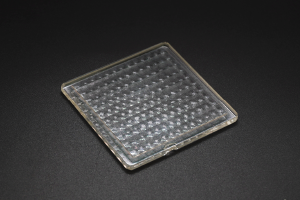

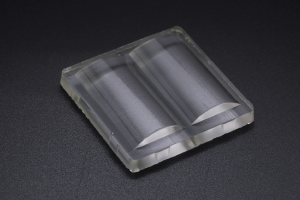

By utilizing the manufacturing technology for glass forming machines, we are capable of glass lens processing (heat forming) including aspheric lens that requires high technology.

Capable of aspheric lens manufacturing which is impossible with the conventional polishing processing.

Machines to be used

T-GM Type Glass Mold Forming Machine

It is a forming machine Takeuchi Manufacturing designed and manufactured for manufacturing precision glass elements. It operates heating – forming – slow cooling of glass and mold at the same time and is capable of manufacturing of aspheric lens which is impossible with the conventional polishing processing. It is the high-precision forming machine that is capable of annealing temperature curve control (path/schedule) to remove residual stress at the target temperature which is important in the conditions for optical glass forming and has a control unit for oxygen concentration which operates in conjunction with that temperature control. We have a joint development system with RIKEN, a National Research and Development Agency, for forming processes and machine improvement, and are in alliance with mold manufacturers and simulation software companies, which enables a one-stop proposal for precision glass elements you desire.

Specifications of Forming Machines

- ■Press

-

Stroke: 80 mm in normal use

Pressure: Control range 0.1 to 5 kN

Speed: 1 - 750 m/min

Drive: Servomotor

- ■Heater

-

Method: Ceramic heater

Temperature: 1000℃

Control: Thyristor (Separate control of top and bottom)

- ■Mold

-

Size: Up to φ60

Number of mold: Top and bottom as a set

Material: Superhard steel or ceramics

- ■Vacuum

- Ultimate vacuum: 6 Pa or less

Example of Manufacturing